The rapid development of electronic communication technology is the engine of modern industry,

and recently it has set off a wave of artificial intelligence.

The realization of these high-tech products is inseparable from the development of semiconductor materials.

The concept of Silicon Valley proposed in the 1970s , which opened the golden age of the first generation of semiconductor silicon materials.

Silicon (Si) is a solid with a high melting point, hard and brittle, and has a silver-white metallic luster.

Compared with semiconductor materials such as selenium and germanium that appeared earlier, silicon, a semiconductor material,

has higher resistivity and conductivity. for higher power circuits. Not only that, silicon materials are also more stable,

so we can jokingly call a wide range of electronic devices and computers now "silicon-based organisms",

especially the brain-"chips", many of which are made of silicon wafers.

The entire production process of silicon wafers,

from the crystal growth in the early stage to the cutting, grinding and polishing process in the later stage,

has been developed very maturely. Most of the polishing liquids corresponding to the silicon wafer polishing process are silicon oxide-based polishing liquids.

Second-generation semiconductors are represented by compounds such as indium phosphide and gallium arsenide.

The third generation of semiconductors, including silicon carbide, gallium nitride, aluminum nitride and other compounds as representatives,

the third generation of semiconductor materials have lower resistivity, which is more conducive to the flow of electrons,

and can be applied to circuits with higher power consumption.

Among the third-generation semiconductor materials, especially silicon carbide materials have advantages.

Silicon carbide materials have high thermal conductivity,

high breakdown electric field, high saturated electron drift speed, good radiation resistance and chemical stability.

Moreover, the development of the silicon carbide material industry is relatively mature, and the production process and technology are also more mature.

Like silicon materials, a silicon dioxide insulating layer can be directly grown on the surface by a thermal oxidation process.

The cutting, grinding and polishing process behind silicon carbide is also becoming more and more mature.

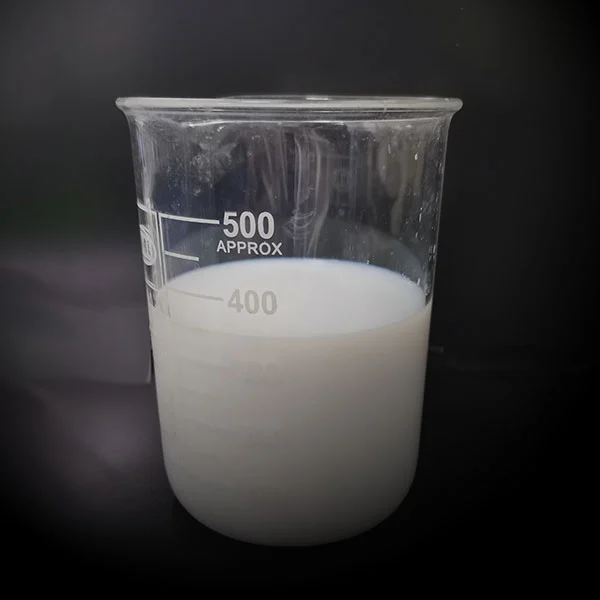

Our company has launched the latest polishing slurry developed for silicon carbide materials, which has high efficiency and good precision.

Our company's latest polishing slurry for silicon carbide materials is based on alumina abrasives and added additives suitable for silicon carbide polishing processes.

Welcome customers to contact and exchange, and purchase trial.