Address:

155 Suhong East Road, Suzhou Industrial Park, Jiangsu Province, China

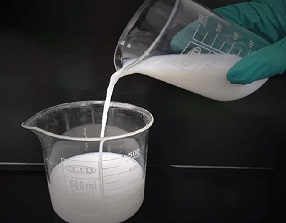

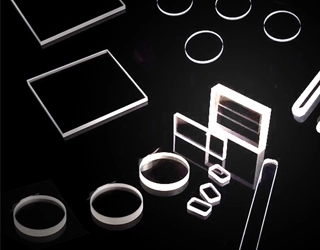

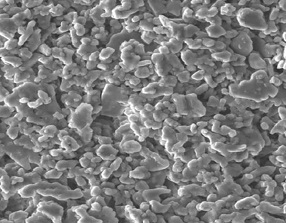

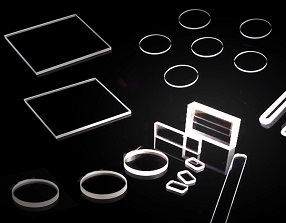

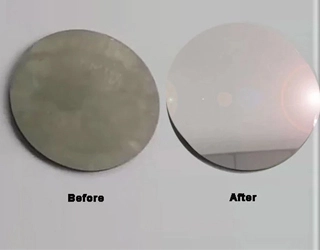

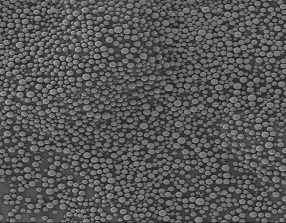

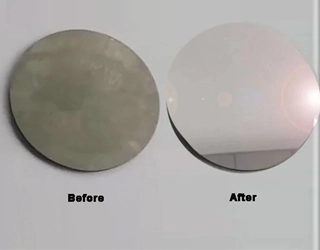

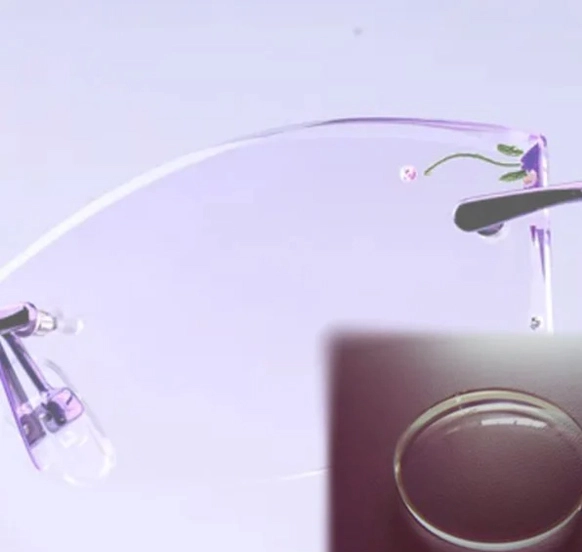

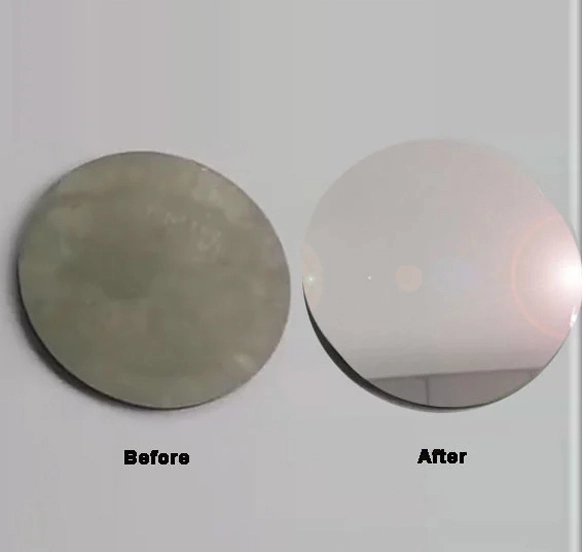

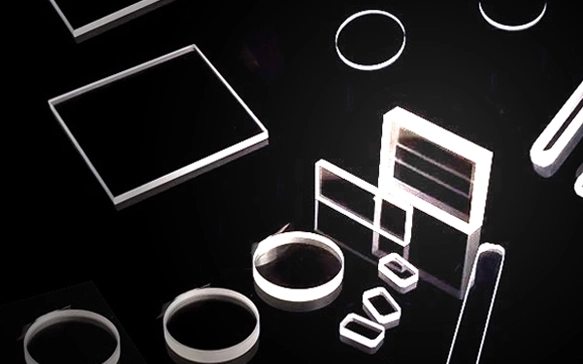

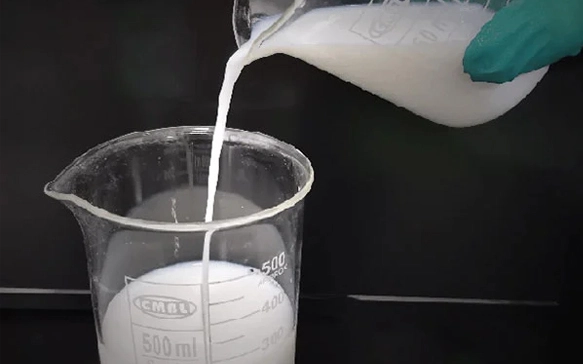

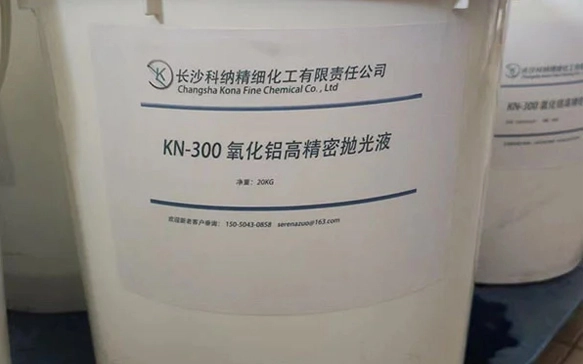

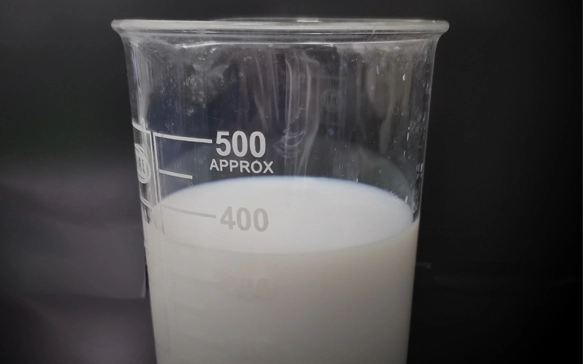

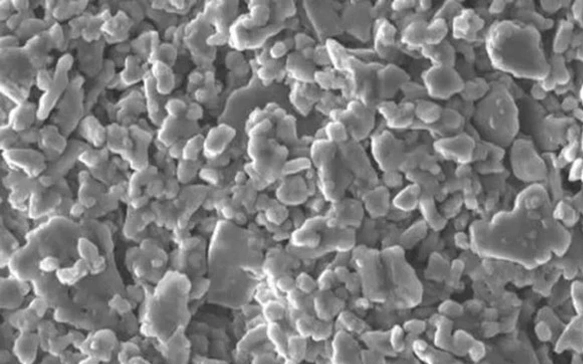

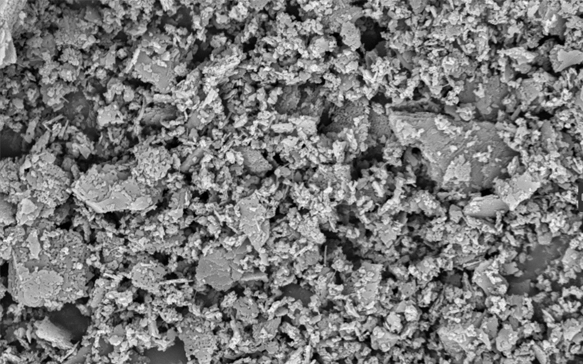

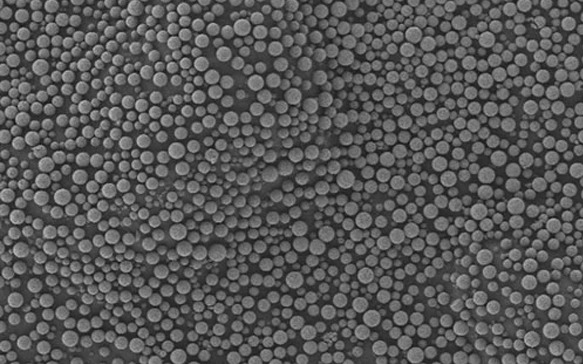

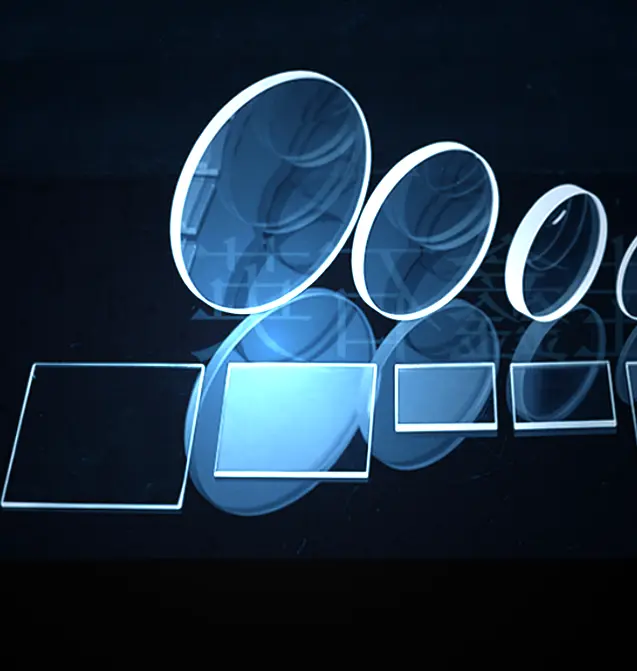

Sapphire (α-Al₂O₃), renowned for its exceptional physical and chemical properties, is becoming an indispensable material in modern industry, particularly in the semiconductor, optoelectronic, and precision manufacturing sectors. As demand for efficient processing techniques increases, significant advancements have been made in chemical-mechanical polishing (CMP), which is crucial for achieving ultra-smooth surfaces necessary for various applications, from LED lighting to high-performance military optics.

EN

EN

cn

cn  ja

ja  ko

ko  de

de  es

es  it

it  vi

vi  th

th  ms

ms  id

id

.jpg)